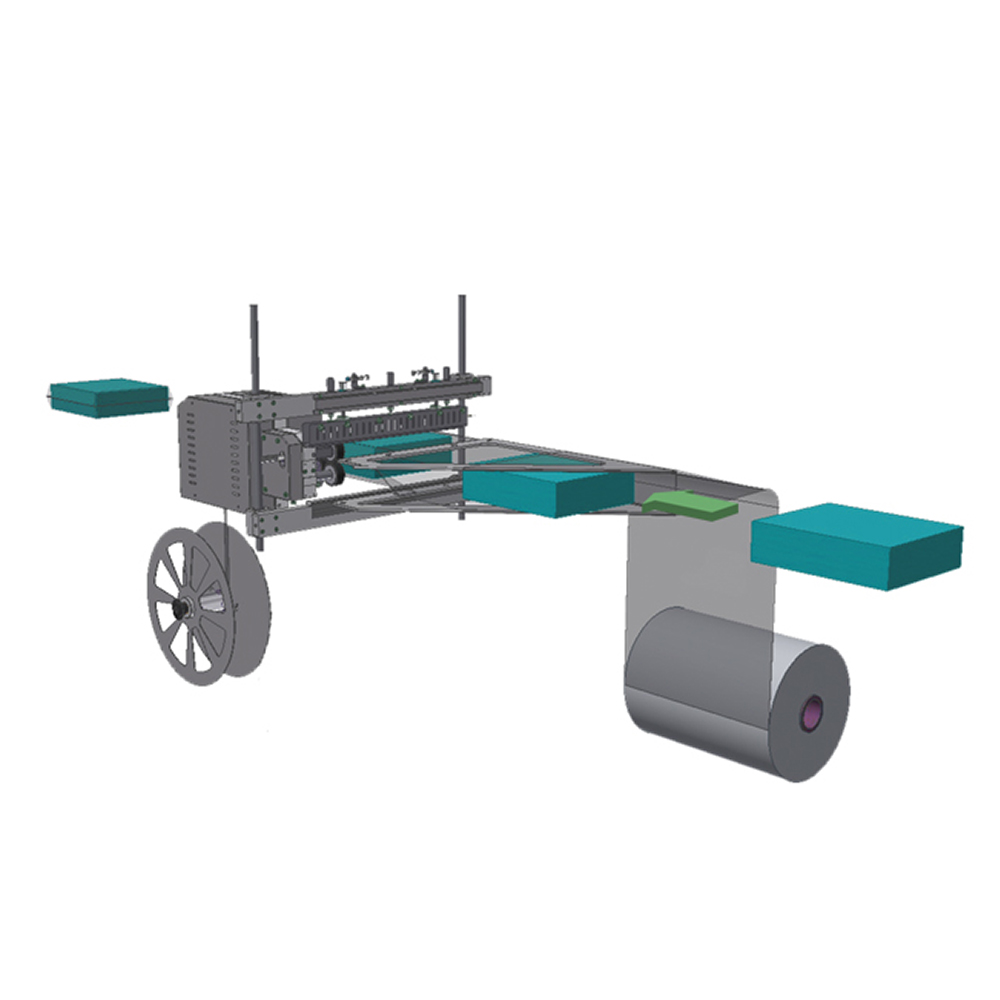

Automatic packaging machine usable with polyethylene and single-fold polyolefin

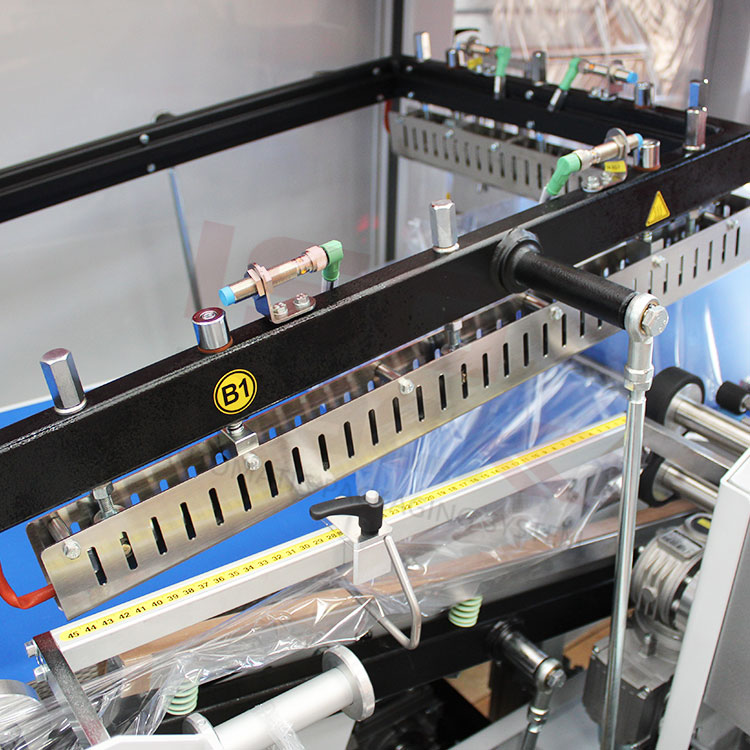

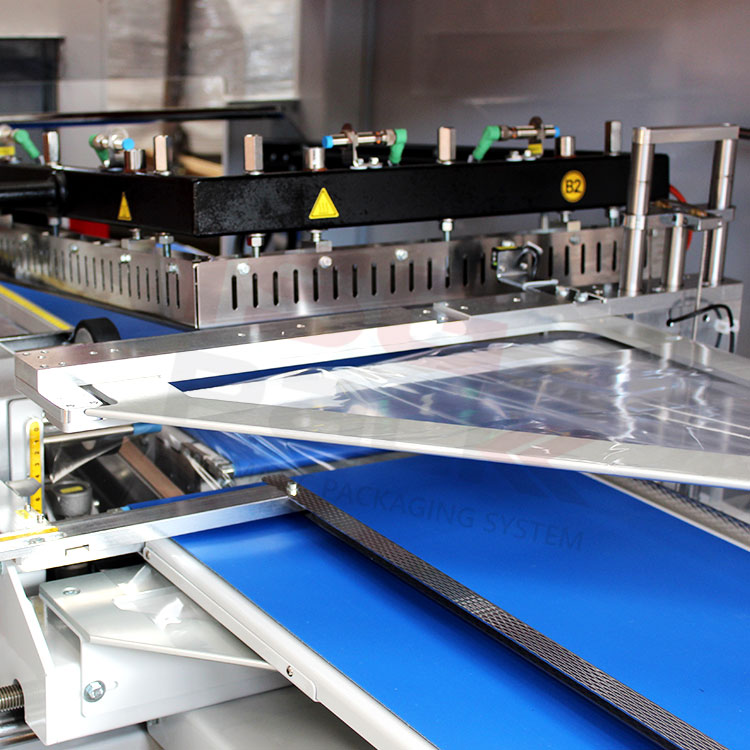

The automatic L-sealers with tunnel, Matic Sealer 65 SC series, have high quality and a very good price and is possible to get it with or without the shrinking tunnel. These machines can work with center folded polyethylene and polyolefin shrink film and the production capacity is up to 3600 packages per hour.These model are characterized by the motorized of the sealing centering.

Use, options and features

REQUEST A FREE QUOTE NOW

SAVE TIME! Make a request to receive our best offer on this product. Alternatively, for more information, you can always contact us at 06.9160.7561.