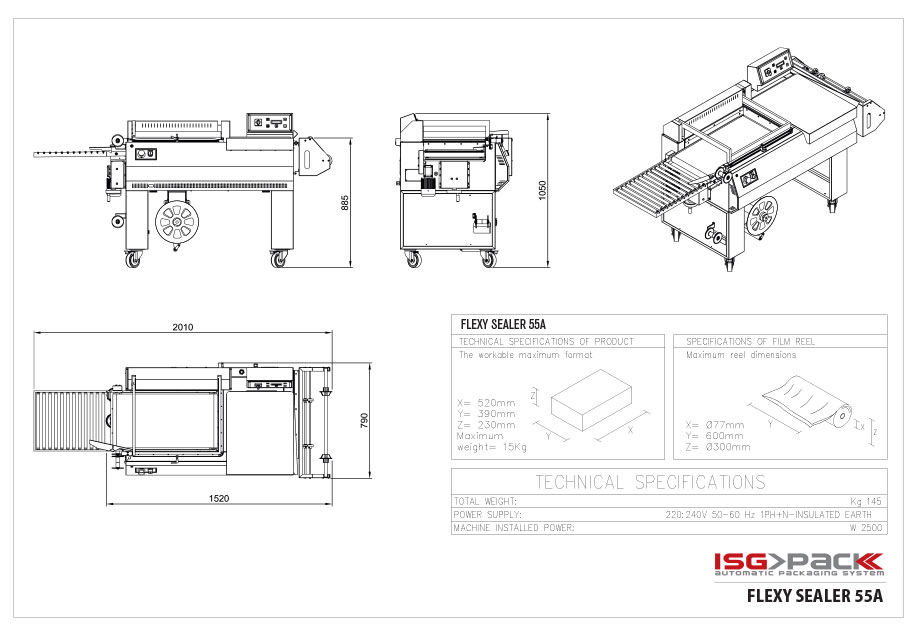

Angular wrapping machine with shrink film for perfect and safe packaging

The semi-automatic L-sealers, Flexi Sealer series, are very functional machines with high quality and competitive price. The Flexy Sealers use a sealing system controlled electronically and advanced safety systems. Thank to the semiautomatic or automatic mode and the creation of customized working programs, these machines are easy to use and have a high production capacity. The Flexy Sealer 55A and 85A can be coupled with the shrinking tunnel S 55 and S 85.

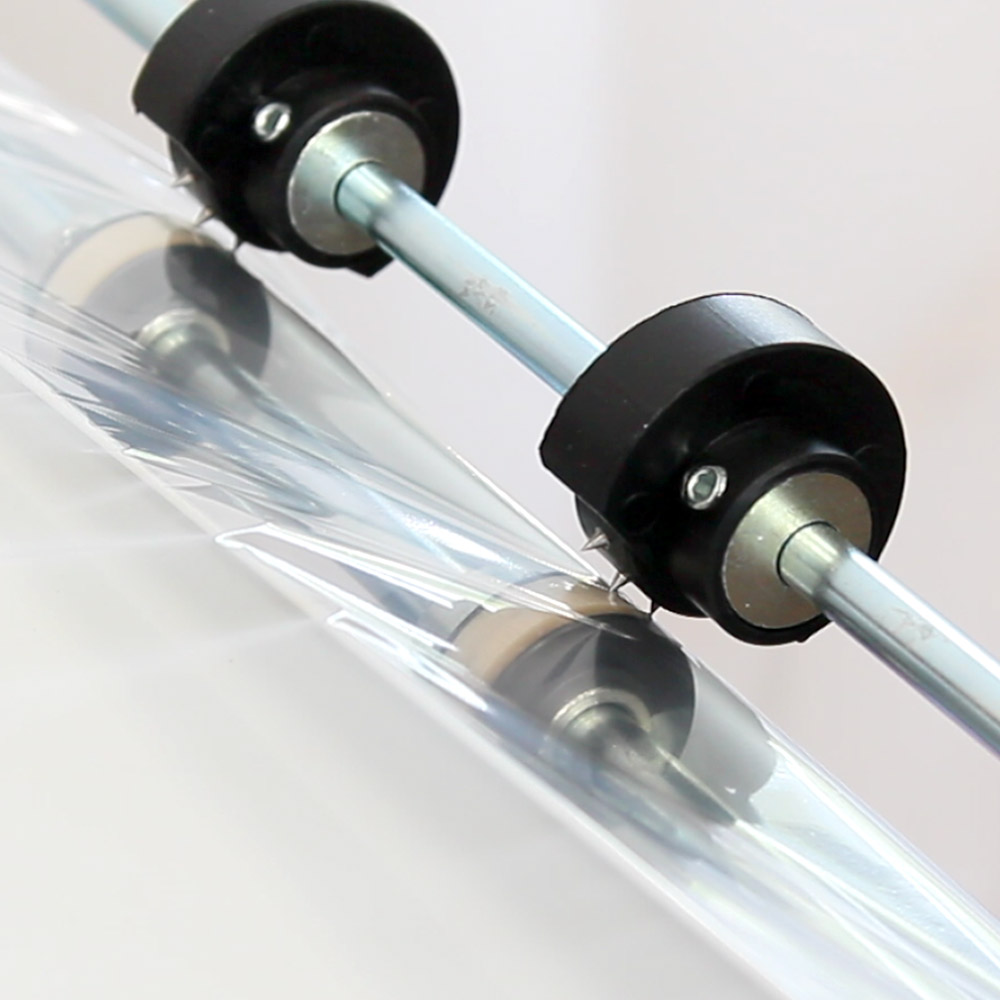

USE: The operator put the product on the working table into the shrink film, guides it inside the sealing area and pushes the start button. The motorized sealing bar goes down and the product is sealed. After sealing, the power bel conveyor moves the product to the shrinking tunnel and then the packed products outfeed.

Optionals and features

REQUEST A FREE QUOTE NOW

SAVE TIME! Make a request to receive our best offer on this product. Alternatively, for more information, you can always contact us at 06.9160.7561.