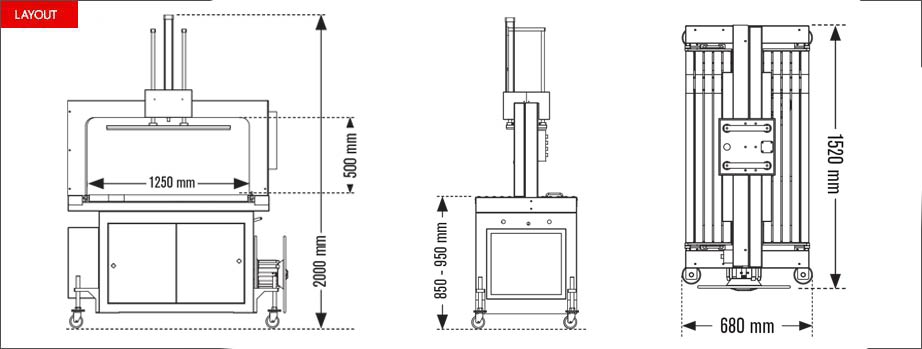

Automatic strapping machine with motorized steel roller conveyor and stabilizing pneumatic press

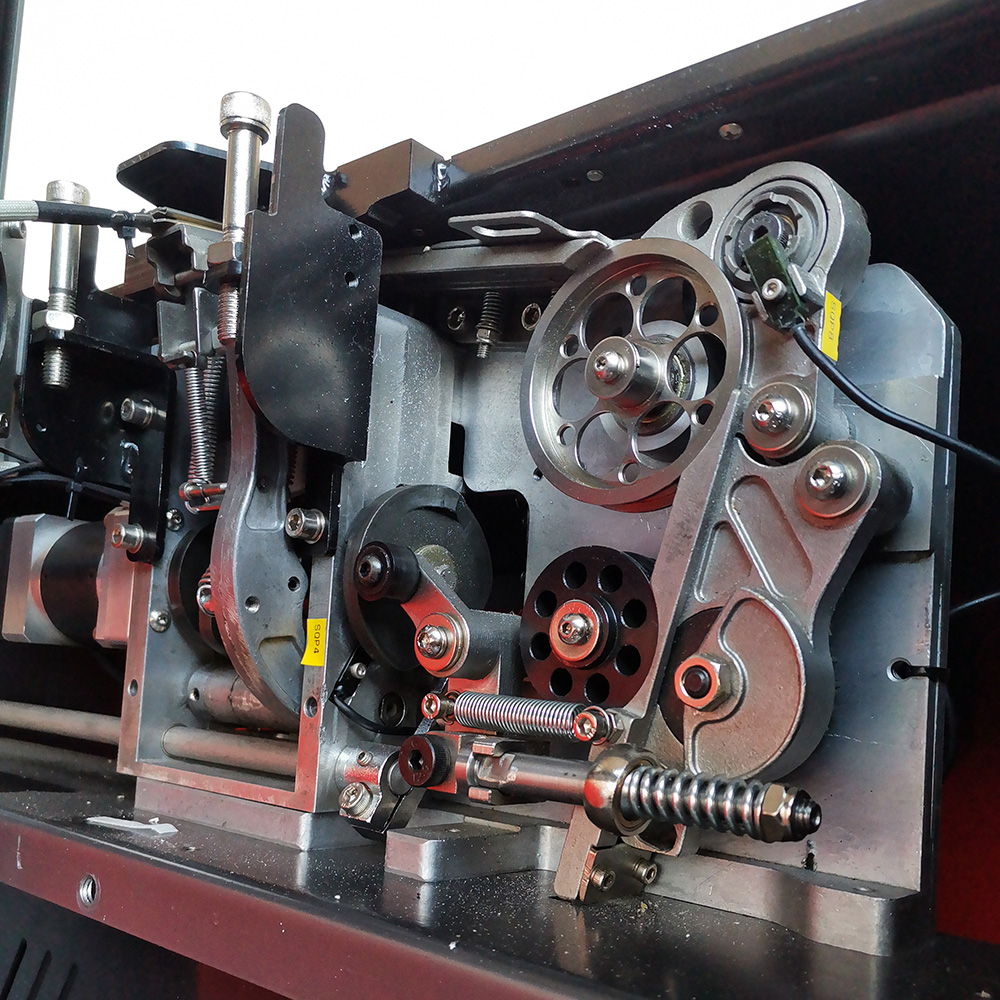

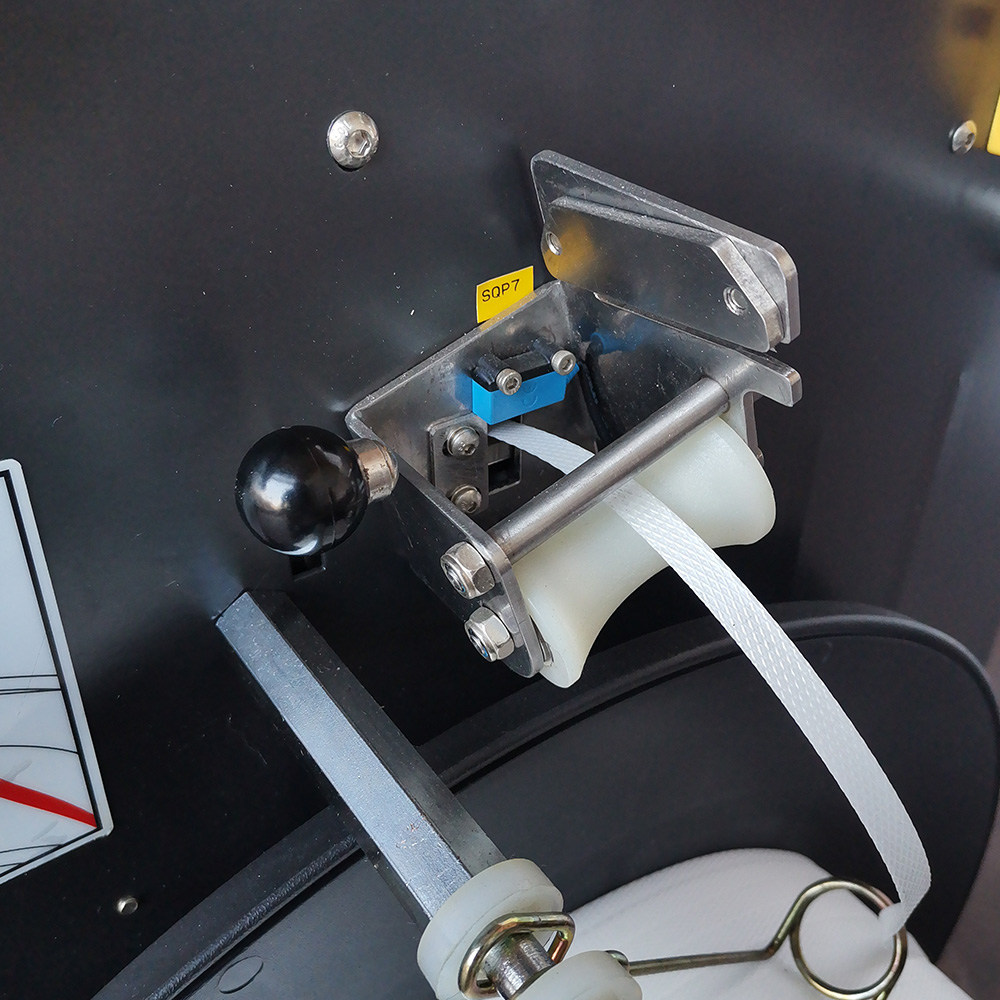

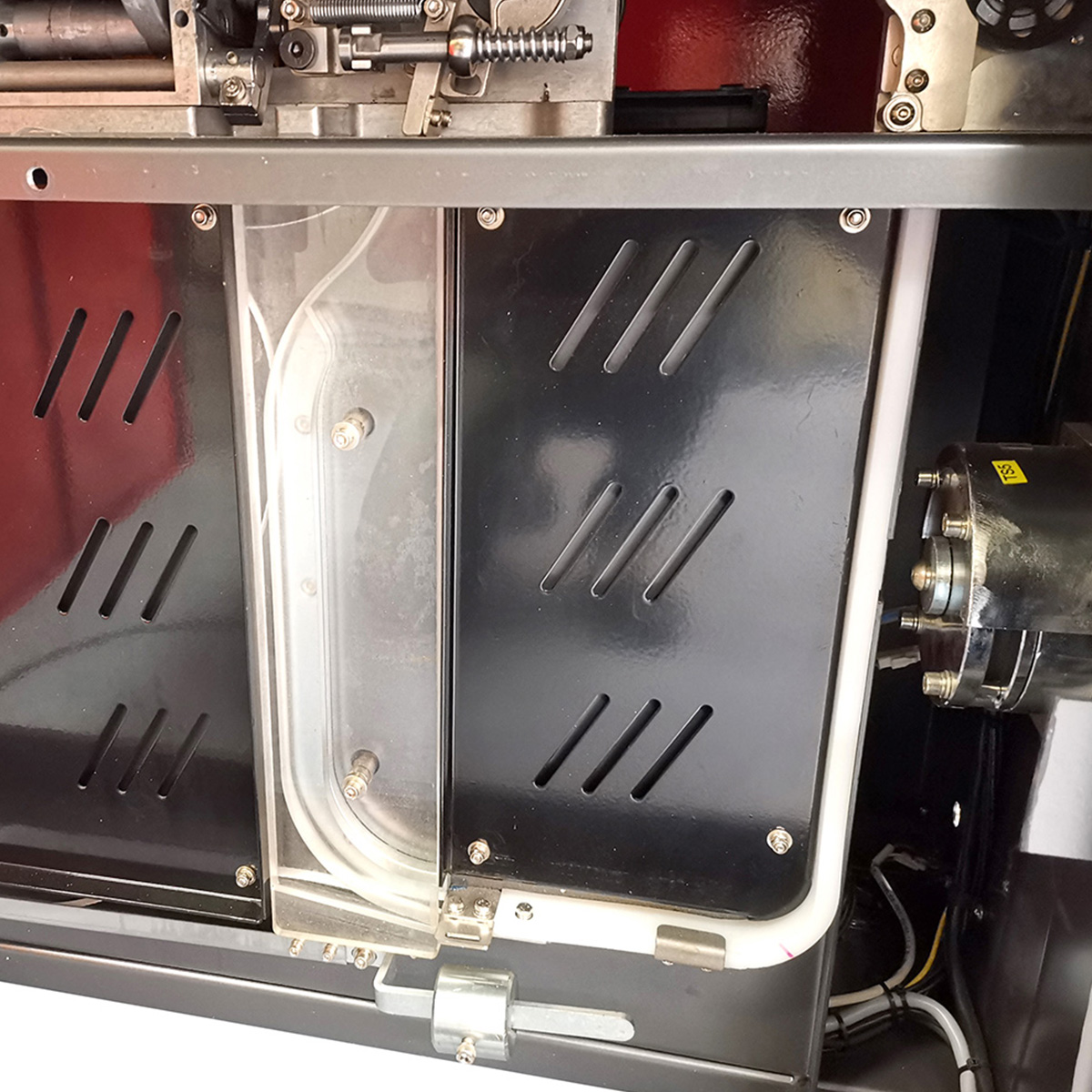

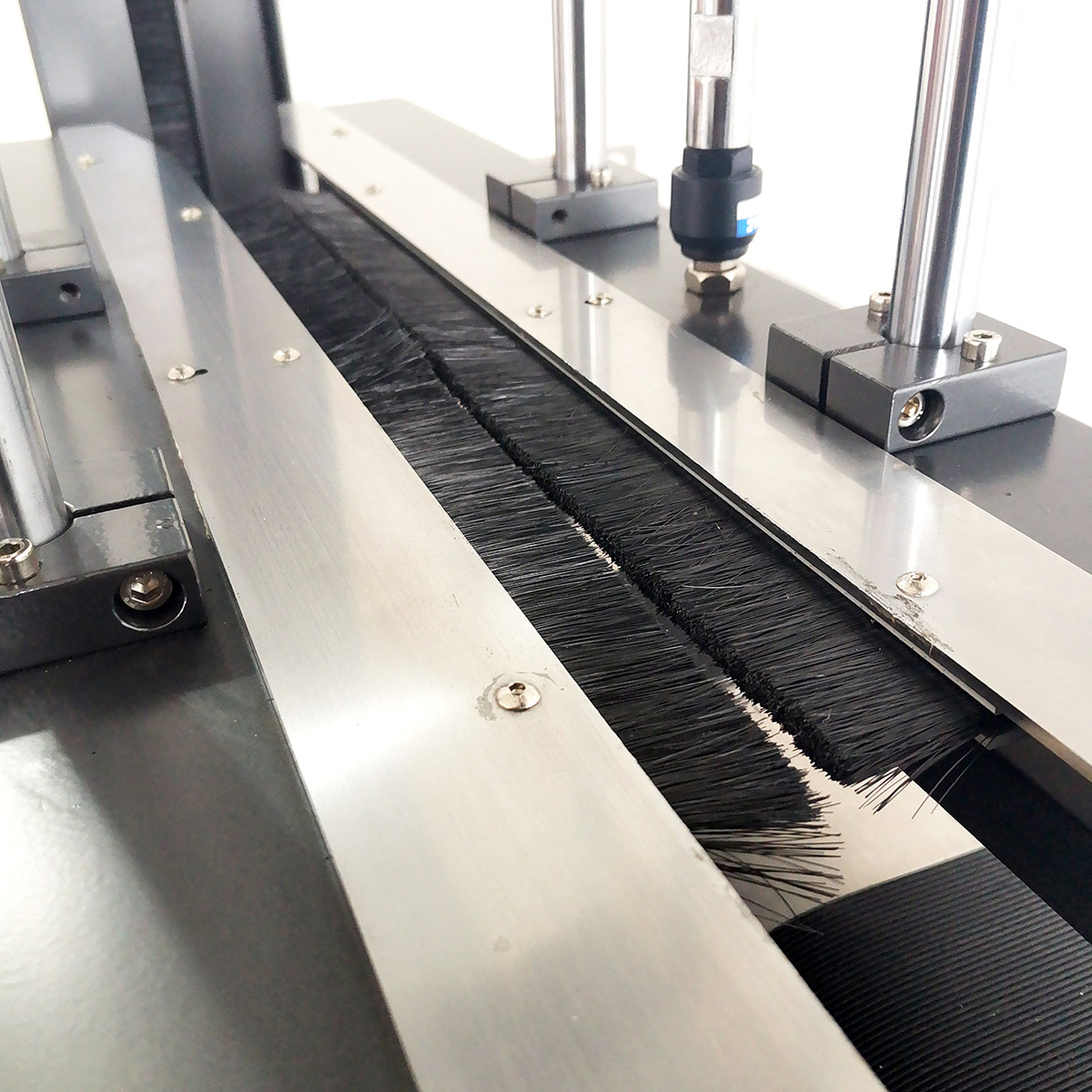

The fully automatic strapping machine, Easy Strap RP series, is a compact, reliable, robust, and easy to use machine. It is equipped with a top press to stabilize the products to strap. It can be inserted in fully automatic production line, ensuring medium-high working capacity. The working table is equipped with motorized roller conveyor and machine can automatically work with 1-2 or multiple strappings through photocells system, adjustable by 180 ° rotating control panel to work on both sides of the machine. It works with DC motors that control each function of the machine. Compared to a traditional strapping machine, more than 30% of mechanical components have been eliminated. Available in SUS 304 stainless steel version.

Features and parameters of the strapping machine

REQUEST A FREE QUOTE NOW

Make a request to receive our best offer on this product. Alternatively, for more information, you can always contact us at 06.9160.7561.