Semi-Automatic strapping machine with digital control panel

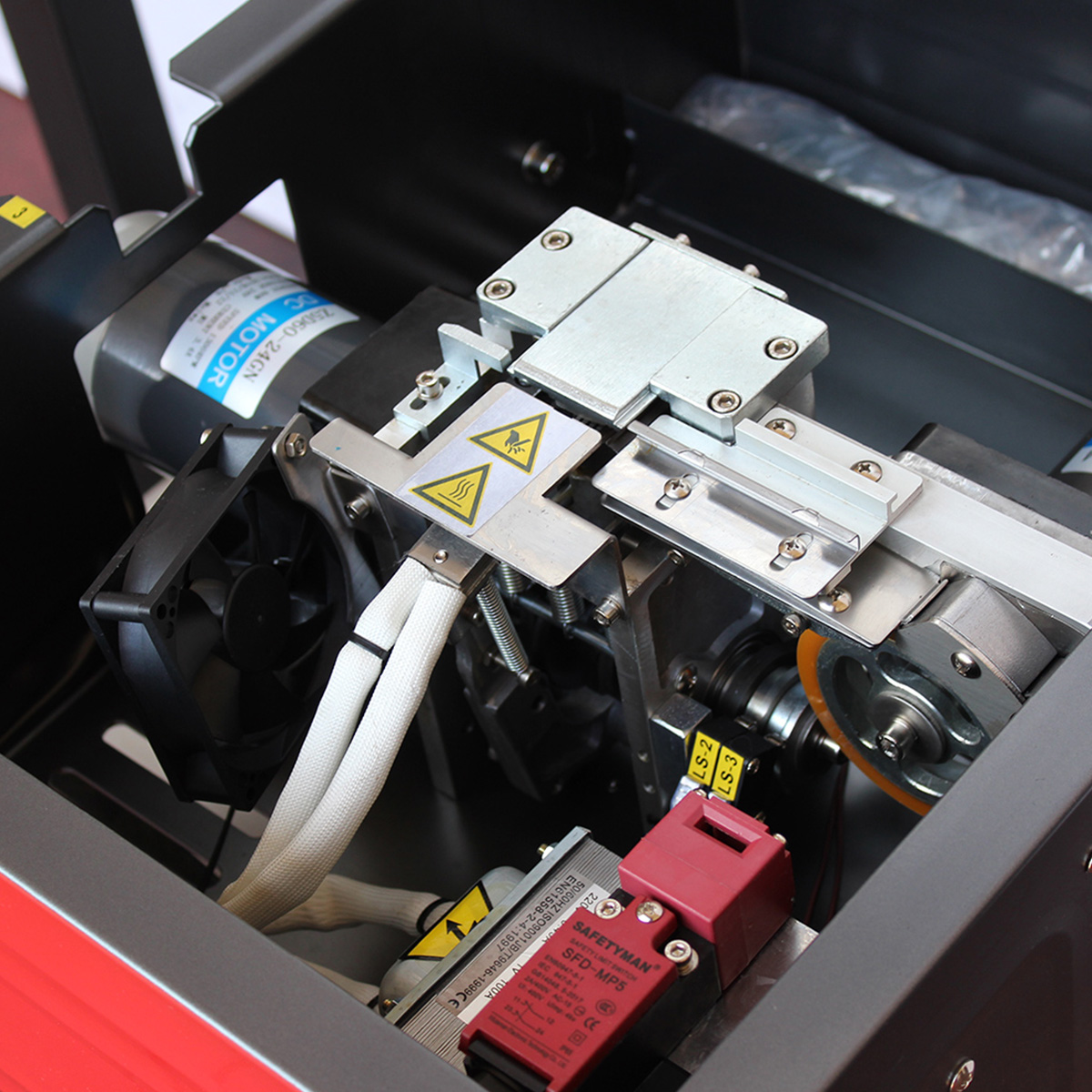

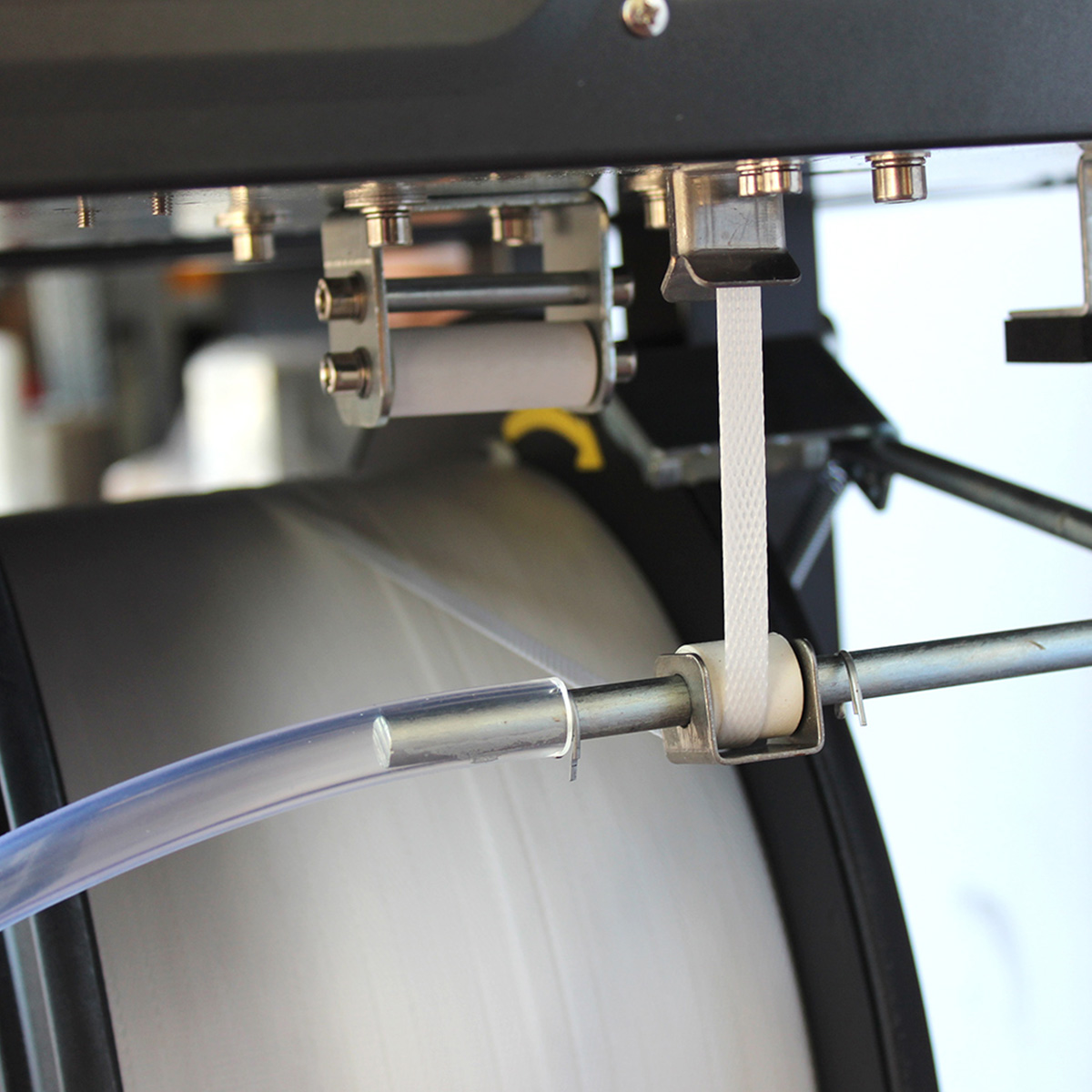

The Eco Strap 501 EVO semi-automatic strapping machine is a next-generation solution designed to deliver reliability and efficiency in packaging operations. Equipped with DC motors dedicated to each function, it ensures accurate and optimized performance. The integration of a user-friendly digital control panel allows for easy adjustment and storage of key operating parameters, making the machine highly adaptable to various application needs. Thanks to its swivel casters, the strapping machine can be easily moved within the workspace.

Compact and versatile, the Eco Strap 501 EVO is ideal for general-purpose use with low to medium workloads. Perfect for strapping boxes, parcels, and bundles, it is suitable for use in warehouses, offices, retail stores, supermarkets, and any environment where secure and reliable packaging is essential.

Functions of the New Digital Control Panel

Thanks to the digital control panel integrated on the front of the machine, various operating functions can be easily and precisely configured. These include strap feed, tension level, sealing temperature, and cooling time. The panel also features a reset button, a manual strap feed control, and a cycle counter function for tracking the number of operations performed.

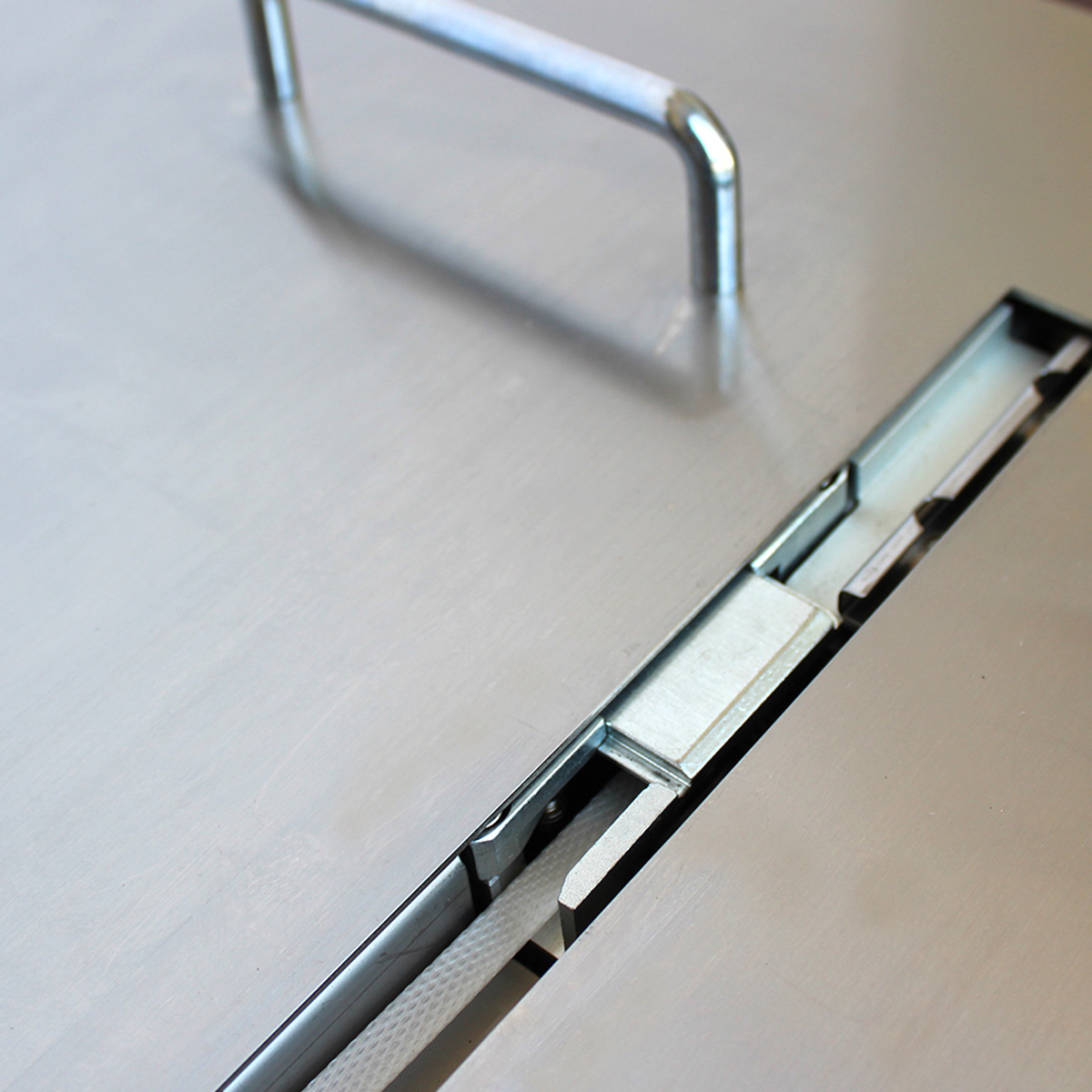

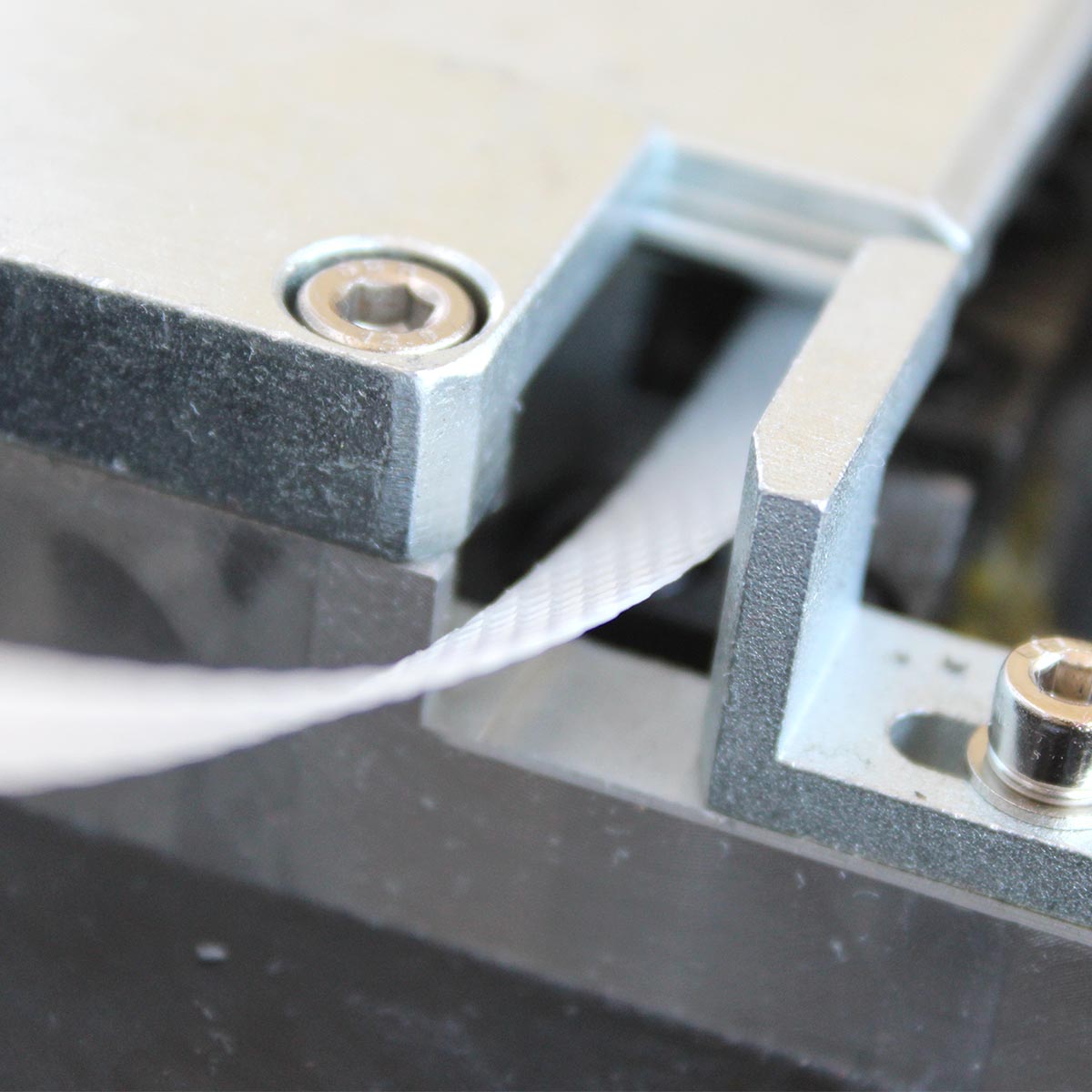

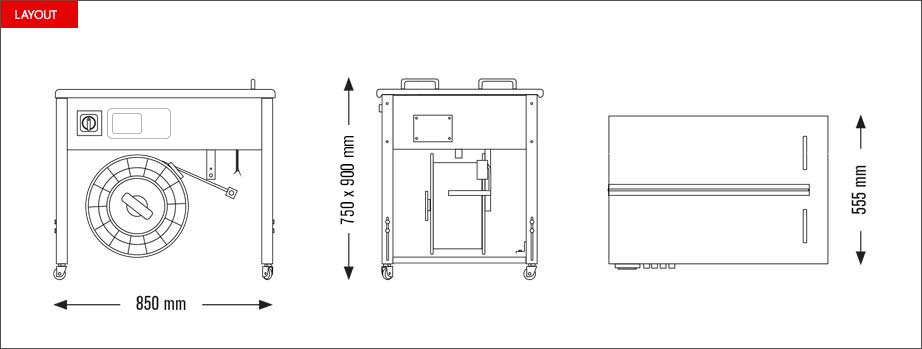

Layout reggiatrice semiautomatica Eco Strap 501 EVO

Features and parameters of the strapping machine

REQUEST A FREE QUOTE NOW

Make a request to receive our best offer on this product. Alternatively, for more information, you can always contact us at 06.9160.7561.