Semi-automatic strapping machine

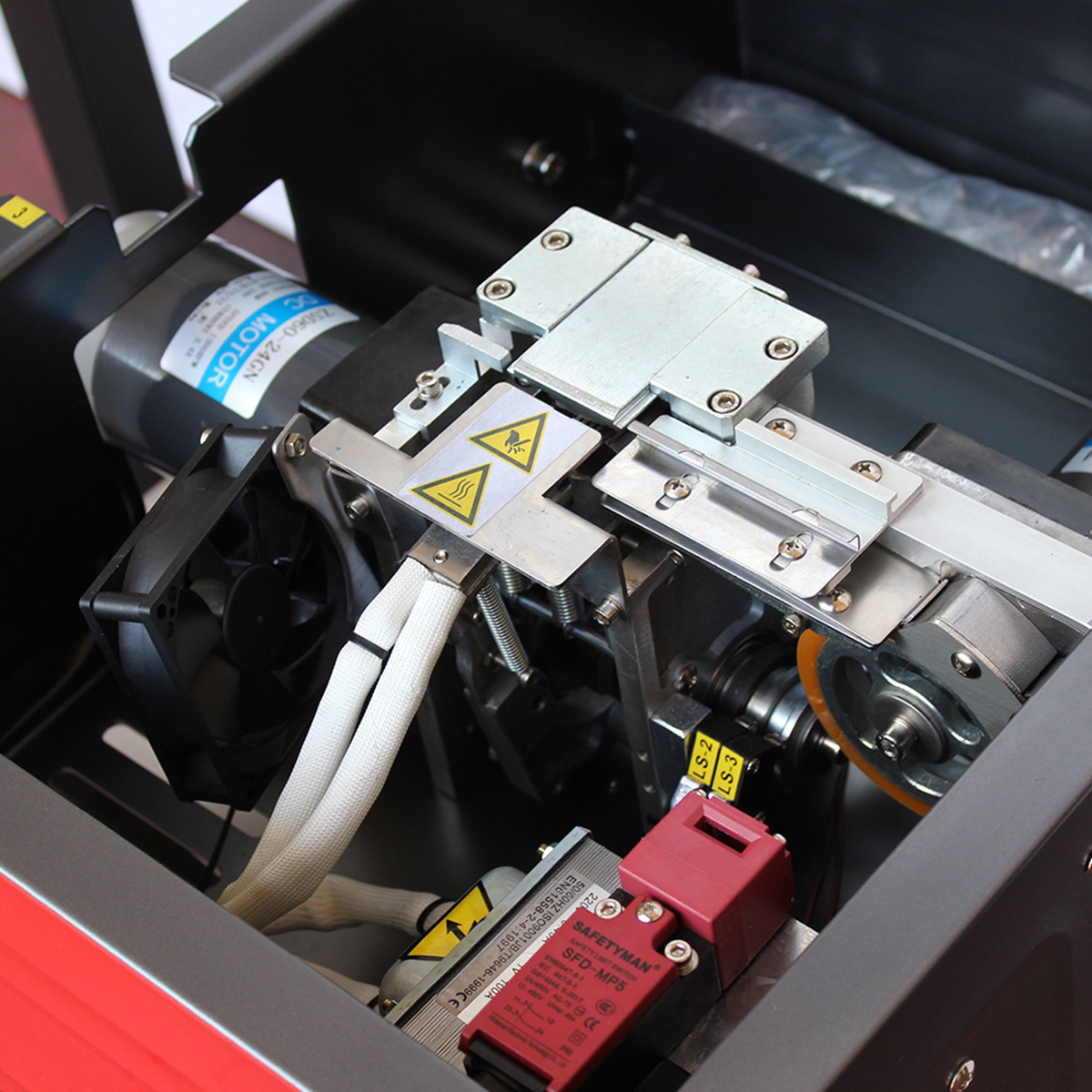

The new generation semiautomatic strapping machine, mod. ECO STRAP 501, is equipped with DC motors that control each function of the machine and it has an electronic strap tensioning adjustable by potentiometer placed on the control panel. Thanks to its pivoting wheels, it can be easily moved and located according to the warehouse needs. Very competitive price and compact strapping machine, extremely efficient for any medium-low working capacity. It is suitable for boxes, packages, bundles strapping. It can be used in warehouses, offices, supermarkets, shops, logistics, anywhere a safe packaging is required.

Operation

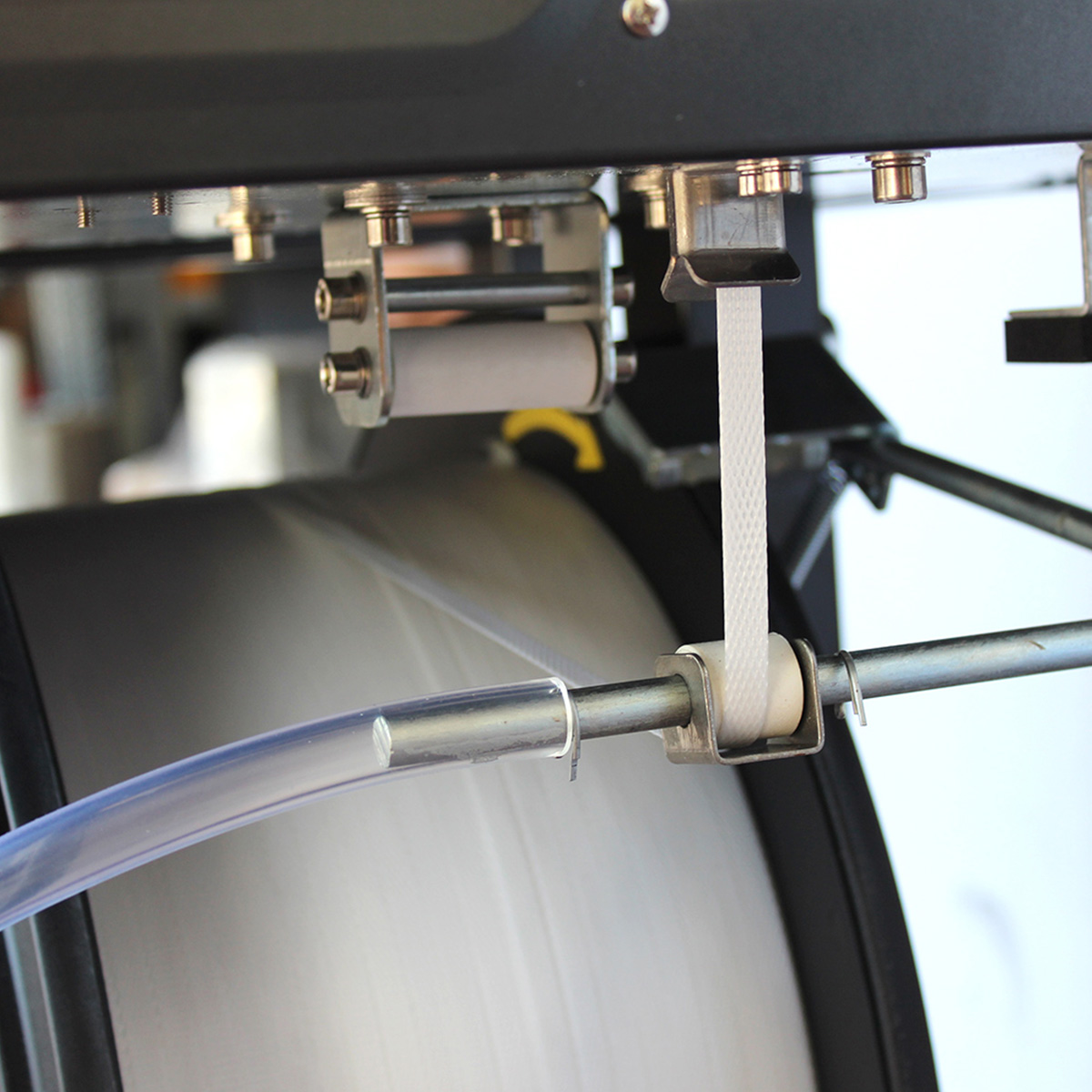

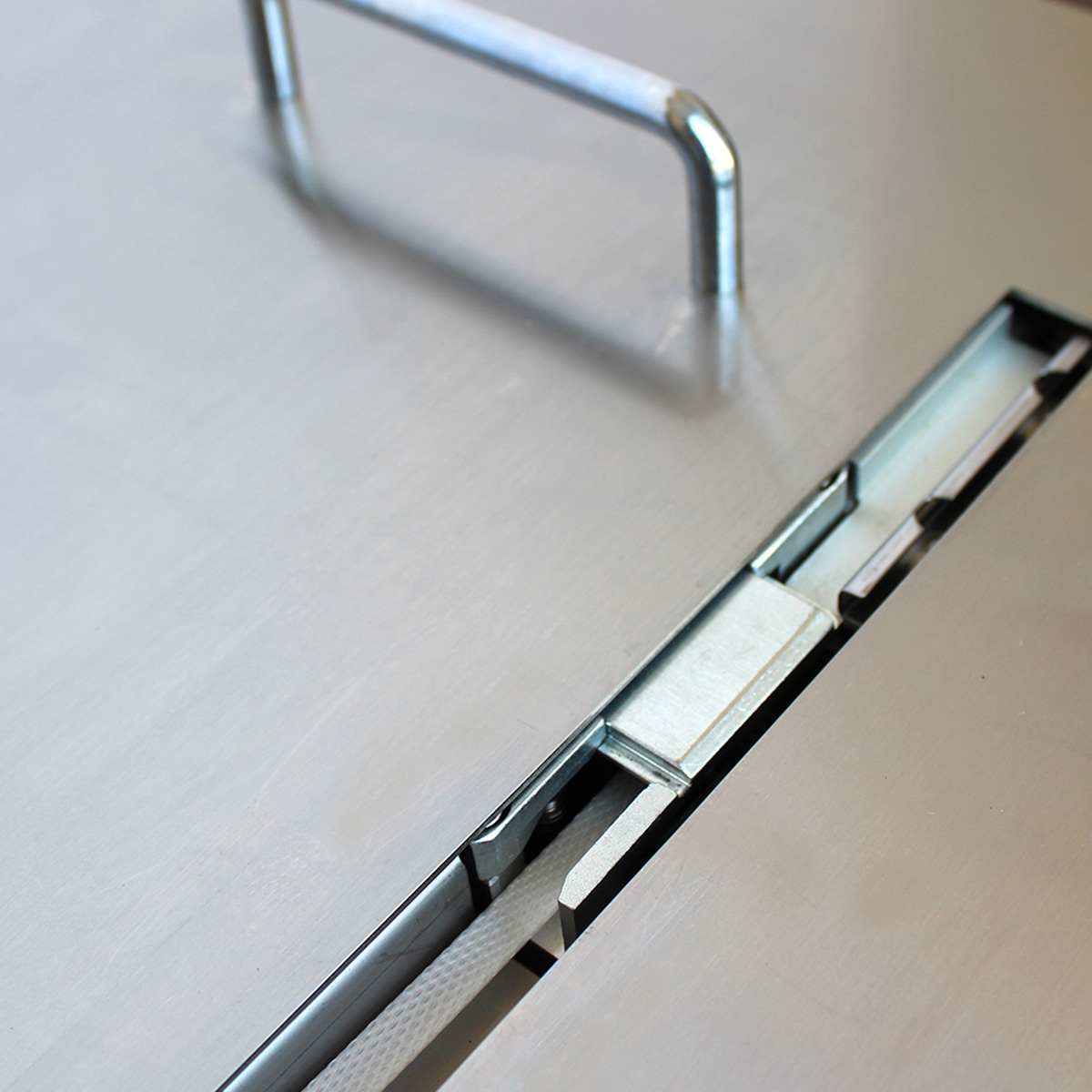

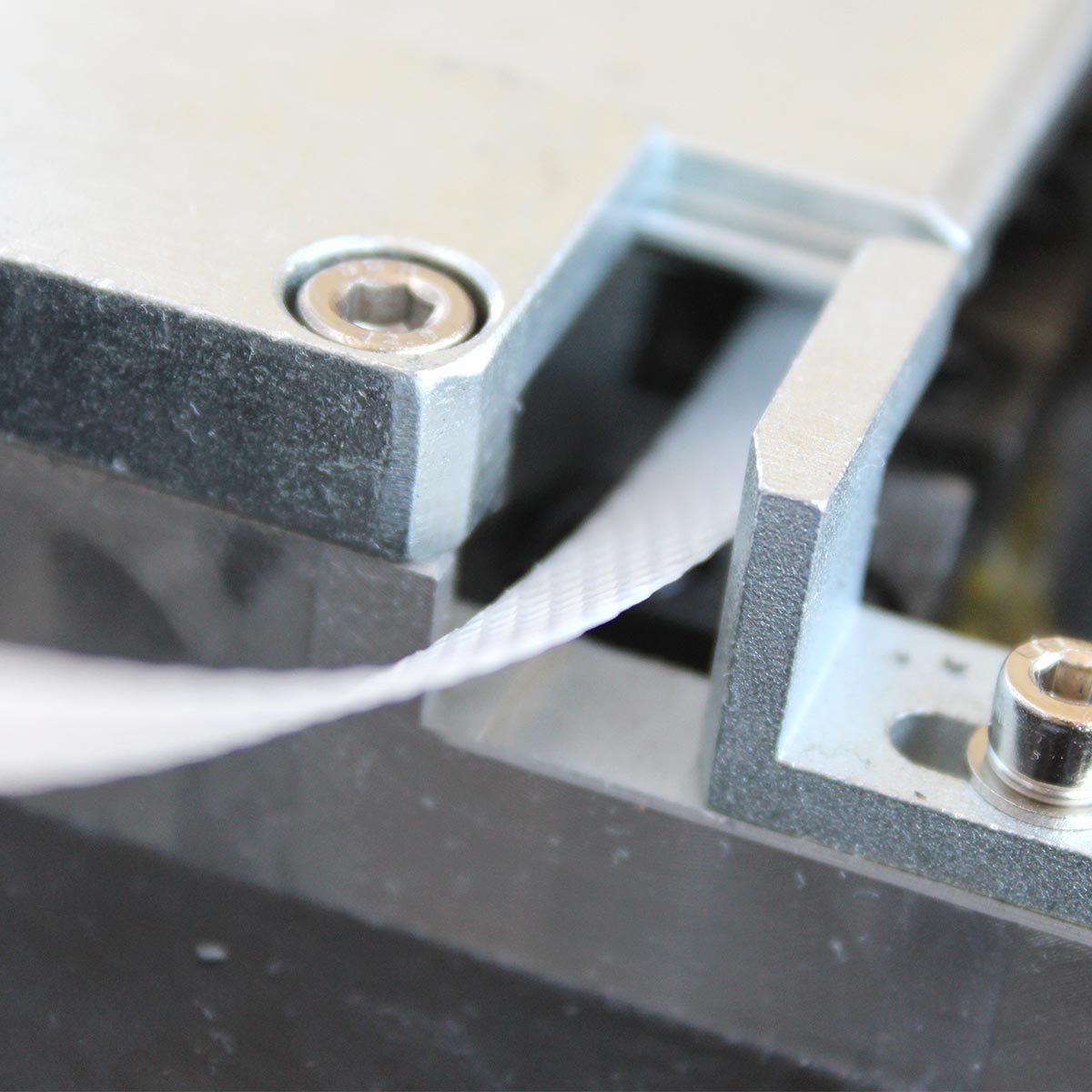

Place the packaging on the work surface of the machine in contact with the sealing head, take the strap and pass it around the product, insert the strap into the sensor positioned on the strapping machine surface. Once the sensor is activated, the tensioning, cutting and welding operations take place automatically.

General characteristics of the strapping machine

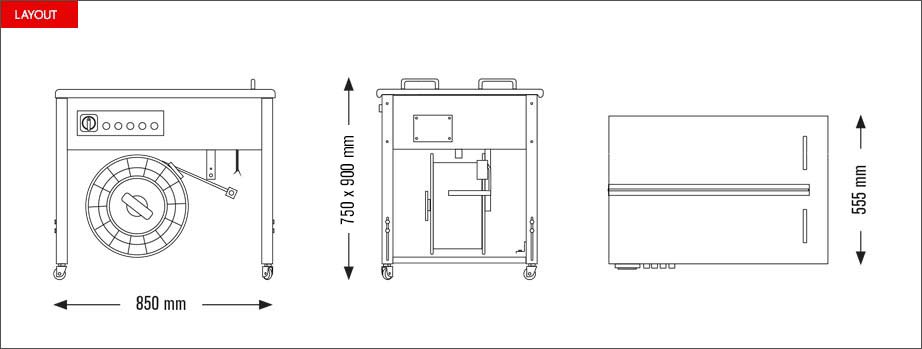

The Eco Strap 501 semi-automatic strapping machine uses a 220 V power supply | 1 ph | 50/60 Hz and has a height of the worktop adjustable in height from 750 to 900 mm. It has a strapping speed ranging from 10 to 15 cycles per minute with a maximum adjustable tensioning force up to 45 Kg. The strapping machine is equipped with four pivoting wheels, two of which with brakes. There is also: adjustment of the welding cooling time (COOL TIME), adjustment of the temperature of the sealing blade, adjustment of the length of the strap to be dispensed, operation of the motors only during the strapping cycle.

Features and parameters of the strapping machine

REQUEST A FREE QUOTE NOW

Make a request to receive our best offer on this product. Alternatively, for more information, you can always contact us at 06.9160.7561.