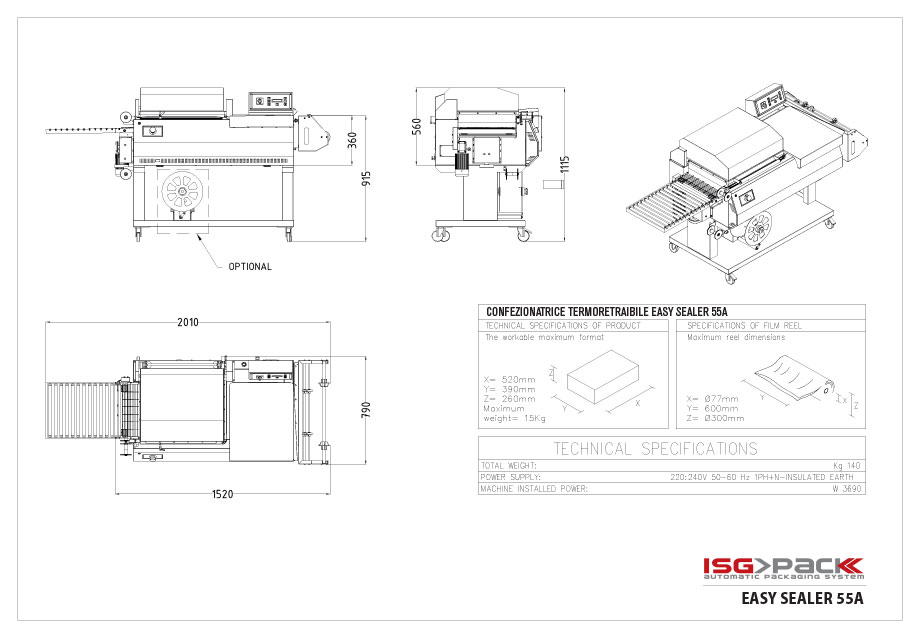

Bell-shaped shrink packaging machine with front control interface

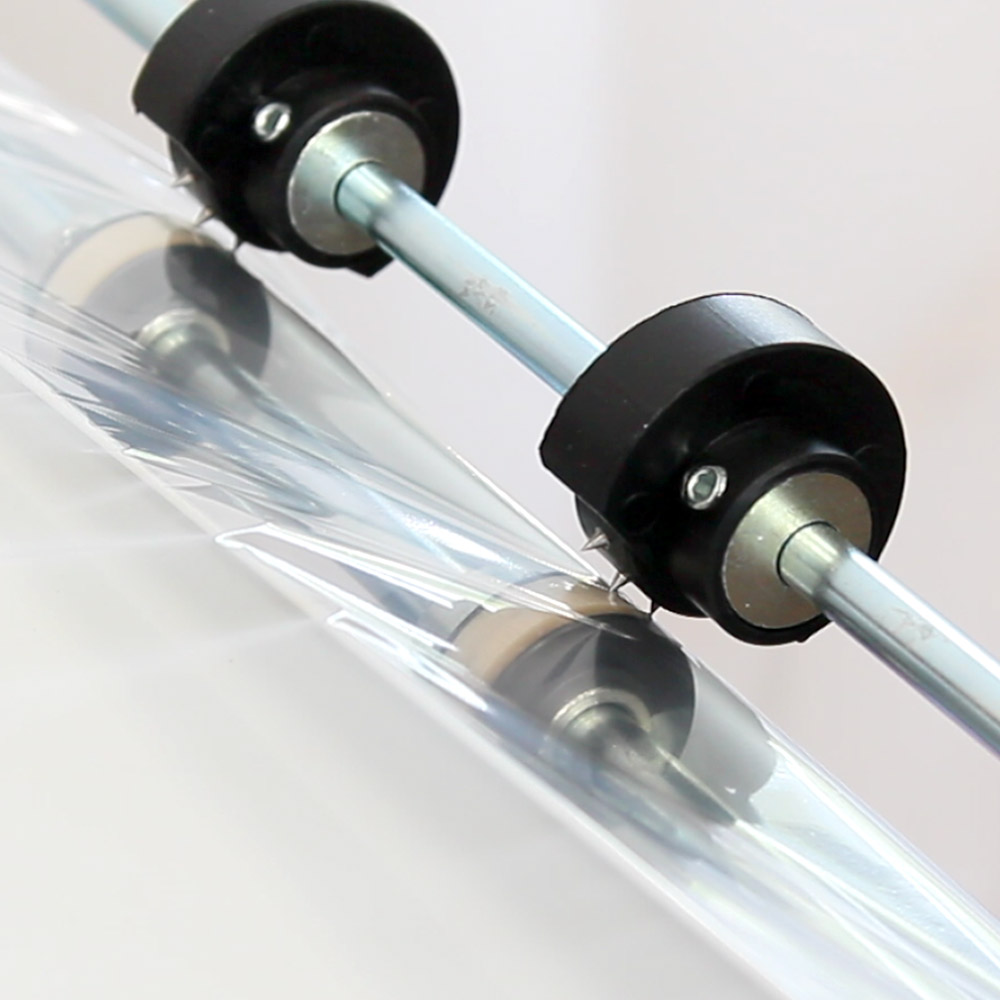

The new chamber shrinking machines Easy Sealer 55 A series, have a solid structure in steel, latest generation electronics with a user-friendly control panel. They have a bigger worktable and several technical details that improve their performances. USE: The operator inserts the product into the shrink film, guides it inside the sealing area and close the chamber. Sealing and shrinking are simultaneous.

Features and optionals of the packaging machine

REQUEST A FREE QUOTE NOW

SAVE TIME! Make a request to receive our best offer on this product. Alternatively, for more information, you can always contact us at 06.9160.7561.