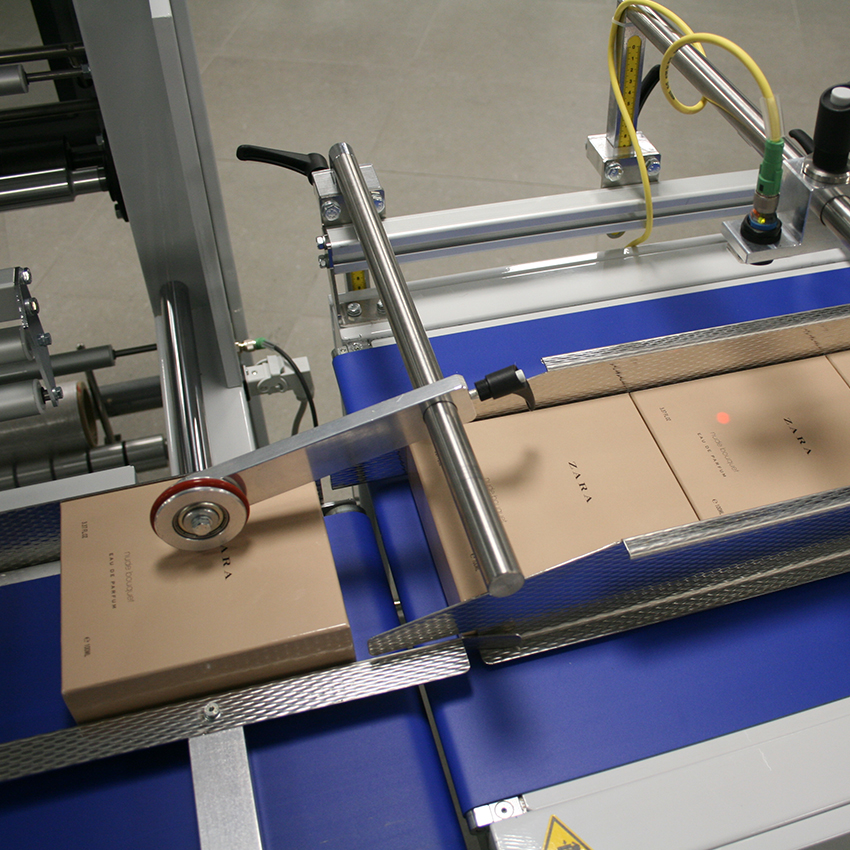

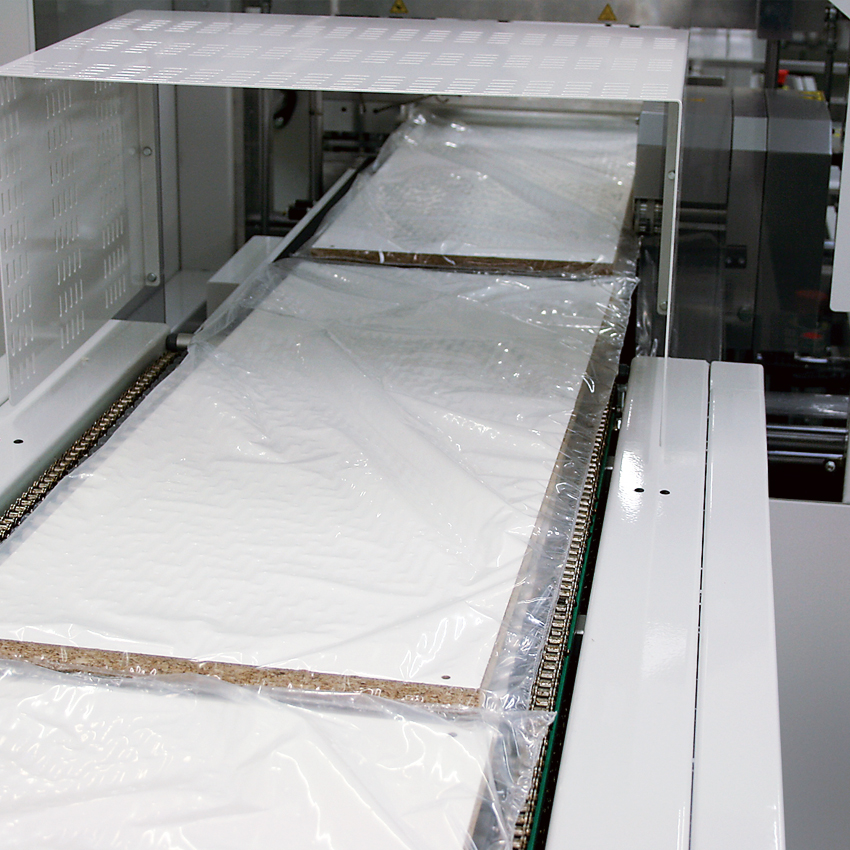

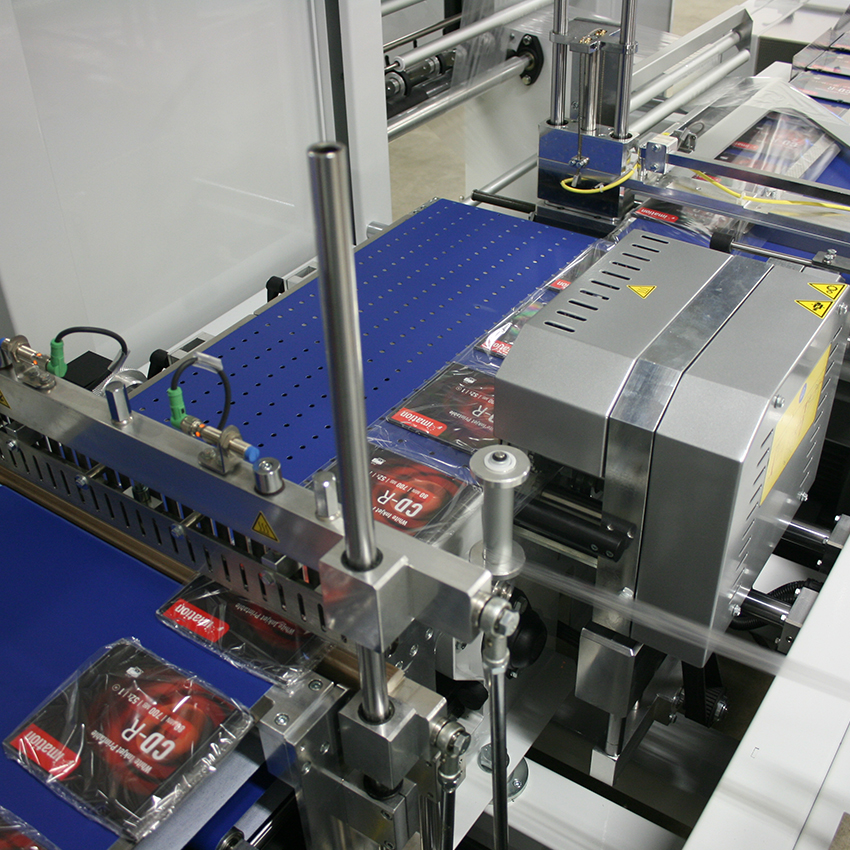

The continuos automatic sealers with tunnel Ultra Sealer 70 HSS, have high quality and a very good price and is possible to get it with or without the shrinking tunnel.Compare to traditional L-sealer,this range offers several

advanteges such as:packaging product with unlimited lenght,increase the production capacity,a significant reduction of film waste. The Ultra sealer series with continuos sealing and INTERMITTENT cycle can handle polyolefin and polyethylene,polypropylene centefolded or flat film with film folder and is suited to meet outputs of up to 6000 packs/hour.

Shrink wrapping machine Ultra Sealer 70 HSS

- Brand: ISG PACK

In stock

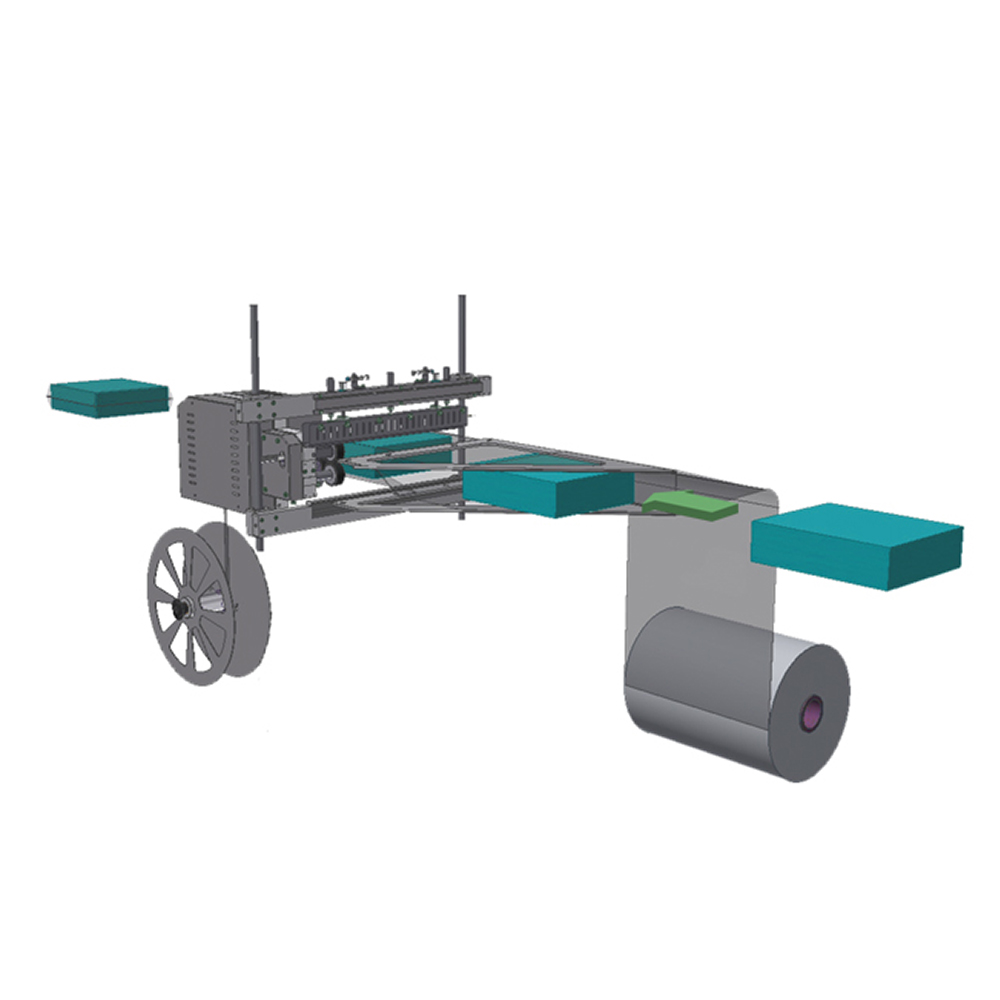

The Ultra Sealer 70 HSS machine is an automatic angular packaging machine that stands out for its excellent value for money and its modularity. It can satisfy productions up to 4200 packages per hour. All models in this range can be supplied with and without retraction tunnel. Compared to traditional machines with angular welding this series offers innumerable advantages such as for example the possibility of packaging products with unlimited length.

WITHOUT

OPERATOR

INSTALLED

POWER 2,5 kW

MAX. PACK

HEIGHT 250 mm.

SEALING BAR

L 700 mm

Additional information

| Dimensione macchina | L 2650 x W 1895 x H 1605 – 1765 mm |

|---|---|

| Peso netto | 950 Kg. |

| Tensione di alimentazione | 380 Volts 3 ph |

| Frequenza di alimentazione | 50/60 Hz |

| Potenza installata | 2,7 kW |

| Dimensione barra saldante | 700 mm |

| Massima altezza prodotto | |

| Produzione massima | 4200 pph |

| Dimensioni massime bobina | 950 – ø 350 mm |

| Film utilizzabili | Polyolefins and Polyethylene |

| Spessore film | Up to 30 my |

Richiedi ora un preventivo gratuito

Effettua una richiesta per ricevere la nostra migliore offerta su questo prodotto. In alternativa, per maggiori informazioni, puoi sempre contattarci allo 06.9160.7561.