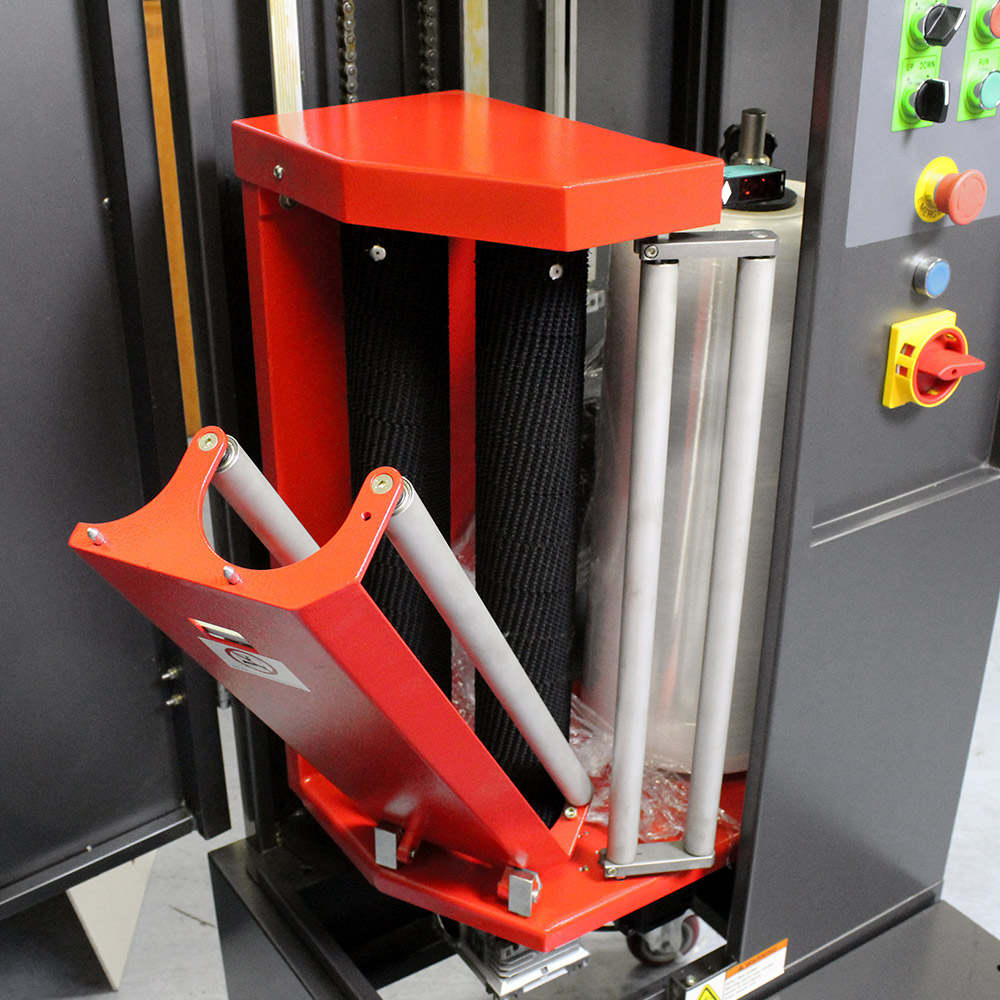

Semi-automatic luggage wrapper with stretch film.

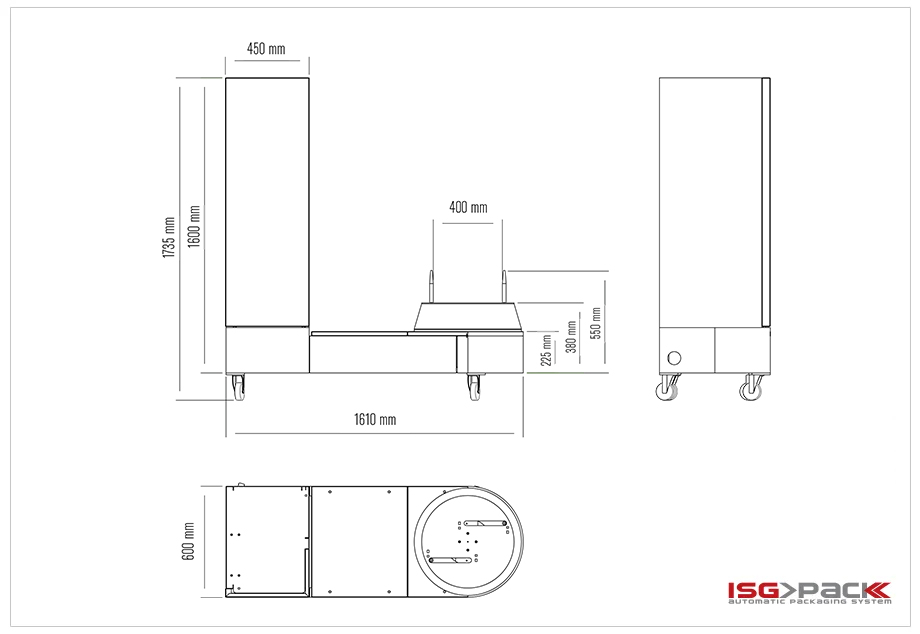

The Baggy Wrap 900 B stretch wrapping machine is a trolley-mounted unit designed to protect rectangular suitcases using stretch film. Equipped with a color touchscreen control panel, it allows the operator to select programs and adjust parameters for a perfect, durable wrap around the luggage.

The new user-friendly graphical interface now available on all Easy Wrap models.

The new software and graphical overhaul developed for the Baggy Wrap 900B stretch wrapping machine will enable even less experienced users to fully exploit the machine’s potential, thanks to simple, intuitive workflows managed via the new 7.2″ color touch display.

General features of the stretch wrapping machine

The wrapping machine is electrically powered and requires an installed power of 1.25 kW. The stretch-film roll for luggage packaging is housed inside the machine, and its carriage features a motorized fixed-ratio pre-stretch system. It can wrap suitcases with maximum dimensions of L 1200 × W 400 × H 850 mm.

Features and adjustments

REQUEST A FREE QUOTE NOW

SAVE TIME! Make a request to receive our best offer on this product. Alternatively, for more information, you can always contact us at 06.9160.7561.