Semi-automatic Easy Wrap 2000 A pallet wrapper with mechanical brake film tensioning

The Easy Wrap 2000 A pallet wrapper is a wrapping machine for palletized loads. Being a semi-automatic wrapping machine, it requires an operator for its operation. The pallet wrapping machine is electrically powered with an energy output of 1 Kw. Film tensioning is done by a mechanical clutch that can be manually adjusted by the operator. Also available as an alternative to this pallet wrapping machine is the Easy Wrap 2000 B with motorized film pre-stretching at fixed ratios.

The new graphic interface user-friendly available now on all Easy Wrap models

The new software and graphic redesign developed for Easy Wrap wrappers will allow even less experienced users to take full advantage of the potential offered by the machine thanks to simple and intuitive work procedures manageable from the new 7.2 color touch display”. SCOPRI DI PIU

General characteristics of the pallet wrapper

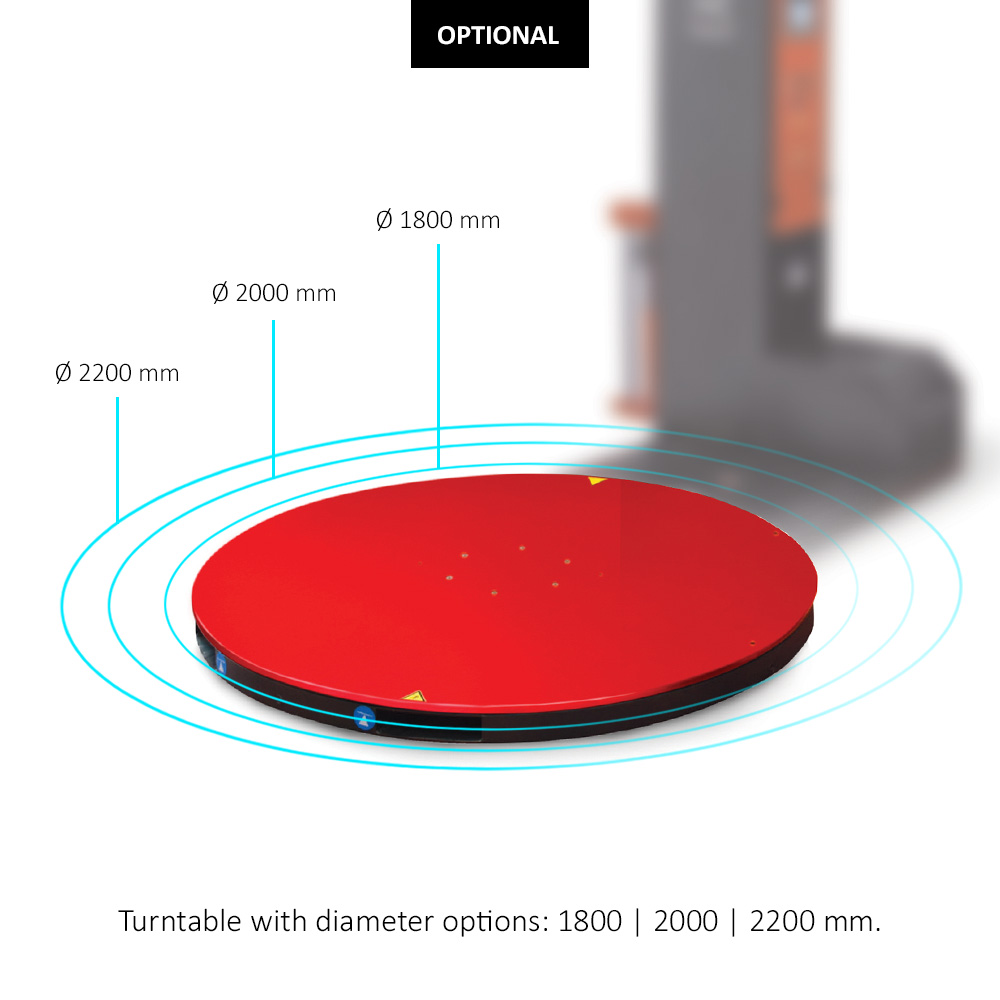

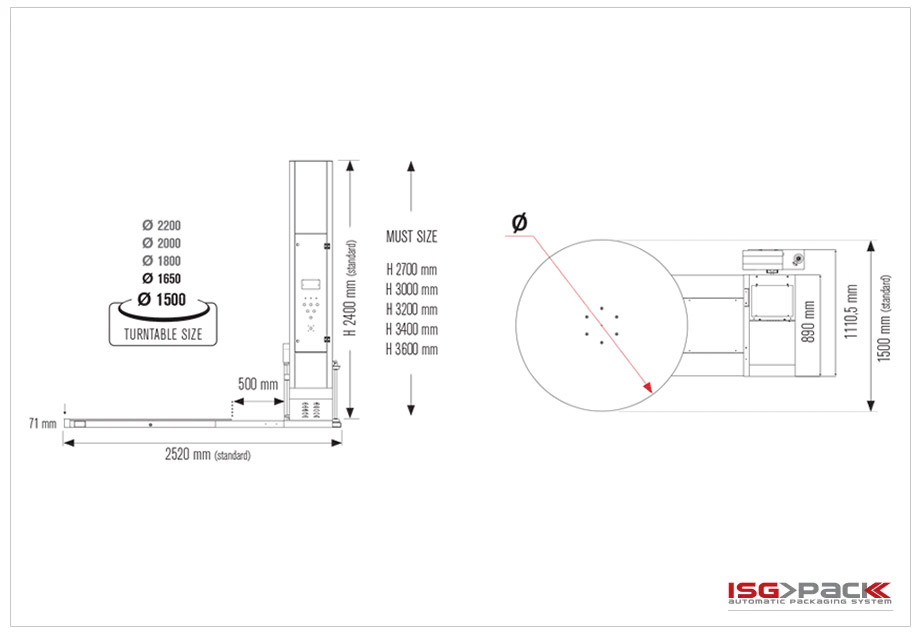

The Easy Wrap 2000 A pallet wrapper has a table diameter of 1500 mm (standard) and can process products with dimensions of L 800 x W 1200 x H 2200 mm, supporting a maximum plate weight of 1500 kg. In addition to the possibility of adjusting the number of film turns on the bottom and top of the pallet, it is also possible to adjust the soft start of the table by inverter. The pallet wrapper is equipped with Siemens PLC and 7.2 color touch screen display.

Characteristics and parameters of the winder

REQUEST A FREE QUOTE NOW

SAVE TIME! Make a request to receive our best offer on this product. Alternatively, for more information, you can always contact us at 06.9160.7561.